Home Page

Explore all categories

VistaPrint Picks: Build your brand on any budget

Marketing & swag to draw in a crowd

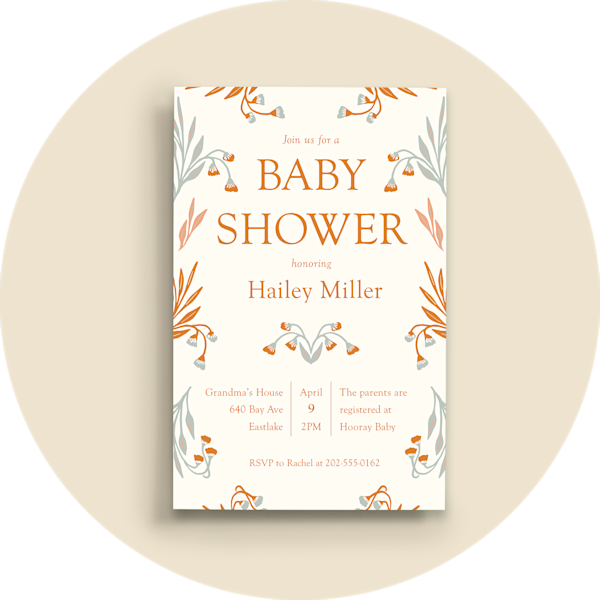

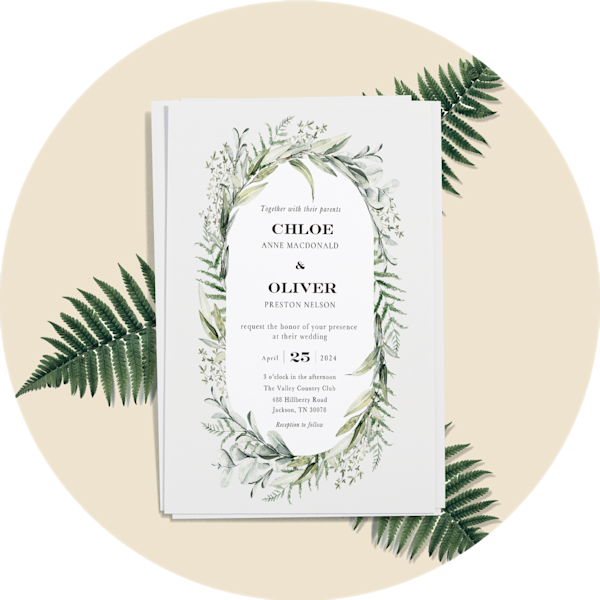

Celebration essentials for every occasion

See all celebrationsStock up & save on business essentials

Tools to help build your business

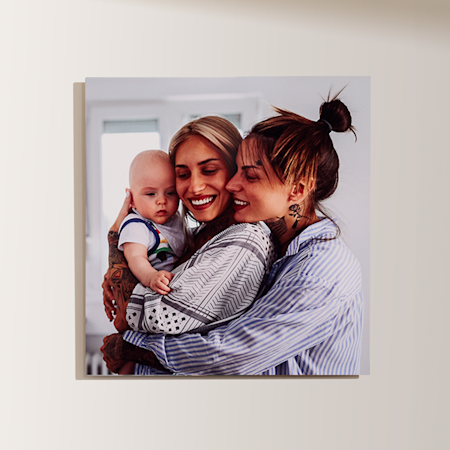

Made by you, #MadeWithVistaPrint

We love to see your custom creations. Post a photo on social media and add @VistaPrint and #MadeWithVista for a chance to be featured here.